DC Motor for DIY 16mm Telecine?

Moderator: Andreas Wideroe

-

electrodist

- Posts: 27

- Joined: Tue Nov 06, 2007 8:32 pm

- Location: Chicago, IL

- Contact:

I'm impressed and am working on my mechanical aptitude.

Here's a post about my first, pre-filmshooting attempt at a telecine.

viewtopic.php?p=174473#174473

Here's a post about my first, pre-filmshooting attempt at a telecine.

viewtopic.php?p=174473#174473

-

electrodist

- Posts: 27

- Joined: Tue Nov 06, 2007 8:32 pm

- Location: Chicago, IL

- Contact:

John, how did you get the 90 degree angle with the aluminum motor mount. It looks like one piece that makes a U in the picture. Is it flat stock bent into shape, multiple flat pieces screwed into each other to make the angle, or a manufactured 90 degree piece?

Also where do you get your aluminum stock? None of the hardware stores around me carry aluminum that thick.

Also where do you get your aluminum stock? None of the hardware stores around me carry aluminum that thick.

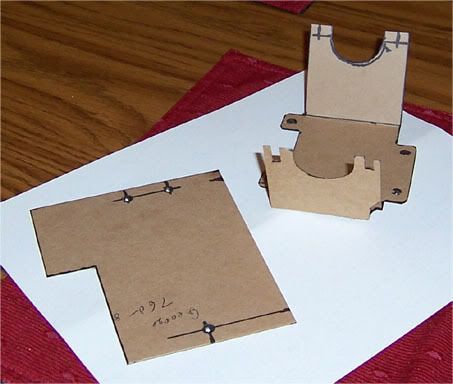

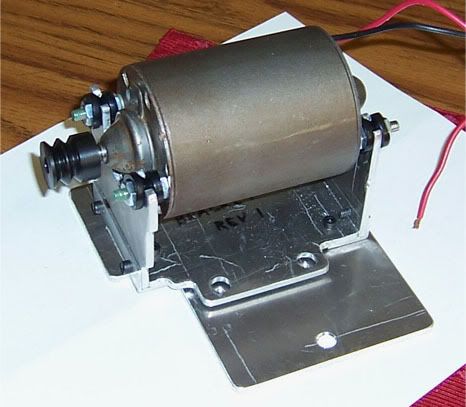

It started as one piece and ended up as three. Below is the cardboard templates I started with.electrodist wrote:John, how did you get the 90 degree angle with the aluminum motor mount. It looks like one piece that makes a U in the picture. Is it flat stock bent into shape, multiple flat pieces screwed into each other to make the angle, or a manufactured 90 degree piece?

I have a cheap metal brake I bought, but I couldn't bend the 1/8" aluminum with it :roll: so I decided to cut the bracket into 3 pieces and assemble them with short pieces of small aluminum angle and hardware.

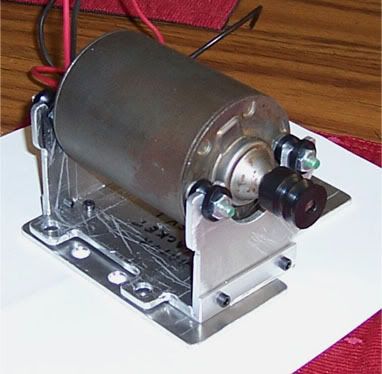

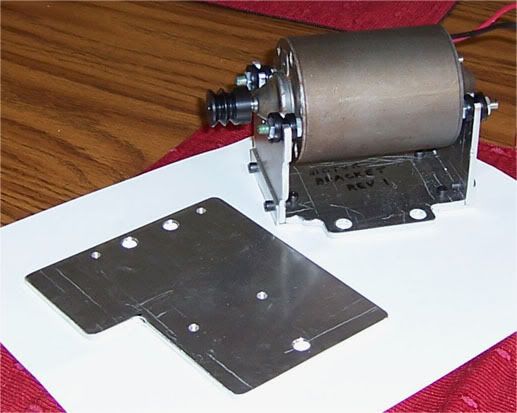

The mounting assembly consists of the motor bracket and mounting plate, which spans the original motor mounting holes:

The aluminum angle can be picked up at your local Home Depot. The aluminum plate I purchased from Speedy Metals. A 12" x 12" piece is more than enough material for the bracket with material left over.electrodist wrote:Also where do you get your aluminum stock? None of the hardware stores around me carry aluminum that thick.

Hope that helps,

JJ

History frozen in the frame of 8mm

-

electrodist

- Posts: 27

- Joined: Tue Nov 06, 2007 8:32 pm

- Location: Chicago, IL

- Contact:

-

electrodist

- Posts: 27

- Joined: Tue Nov 06, 2007 8:32 pm

- Location: Chicago, IL

- Contact:

Frank, wouldn't the optical switch's interrupter disc be best when 50% open and 50% closed? If the problem is with the debounce circuit in the mouse then this would give it equally long signals to open and close the circuit. What would be the reason to have the slot as small as possible, as you suggested?

I can't see a problem with having a larger than necessary slot, providing the PC doesn't slow down during the mousedown period....although it does also depend on exactly how and when the capture software does its frame capture - probably determined by mouse up. Try it and see.electrodist wrote:Frank, wouldn't the optical switch's interrupter disc be best when 50% open and 50% closed? If the problem is with the debounce circuit in the mouse then this would give it equally long signals to open and close the circuit. What would be the reason to have the slot as small as possible, as you suggested?

Frank

Off all the things I've lost, I miss my mind the most.

Re: DC Motor for DIY 16mm Telecine?

Hi, I know that this an old post, but I've a question ?

I've the same project, tochange the original motor of an Eiki, at the beginning i was thinking in use a step motor, but it seem to be impossible to have a "small" that can go up to 24 RPS and have the torque to move all the projector... so maybe a brushless motor is a good idea, but there is something that i can't understand, when you say that the original motor is a 37W ?? In the specification of the Eiki that I've, they said the the original motor is a 140 Wats 110VAC....

So, could something can help to understand wich kind of motor i need to buy to be able to make all the connections ???

I'm thinking to use this board to pilot the motor trough Arduino and a PWM otuput...

LINK : https://shop.ruggedcircuits.com/index.p ... ucts_id=14

Did someone has use it before ??

Thanks in advance for your help...

Best

KinoLab

I've the same project, tochange the original motor of an Eiki, at the beginning i was thinking in use a step motor, but it seem to be impossible to have a "small" that can go up to 24 RPS and have the torque to move all the projector... so maybe a brushless motor is a good idea, but there is something that i can't understand, when you say that the original motor is a 37W ?? In the specification of the Eiki that I've, they said the the original motor is a 140 Wats 110VAC....

So, could something can help to understand wich kind of motor i need to buy to be able to make all the connections ???

I'm thinking to use this board to pilot the motor trough Arduino and a PWM otuput...

LINK : https://shop.ruggedcircuits.com/index.p ... ucts_id=14

Did someone has use it before ??

Thanks in advance for your help...

Best

KinoLab

- miles&jules

- Posts: 24

- Joined: Tue Oct 29, 2002 12:49 am

- Contact:

Re: DC Motor for DIY 16mm Telecine?

Hi guys

We just use motors from cordless 12volt drills. They have plenty of Torque and are cheap as. Our local rubbish tip/recycling place sell old ones for $5 each...or you can by brand new drills for $30. We then control the motor via a forward and reversible dc speed controller(from ebay)

Works great ,you can go slow it to 1 frame every few seconds up to 30+fps.

Works great, might be to noisy for some people but doesn't bother us. We just close the door to that room while its scanning.

Miles

We just use motors from cordless 12volt drills. They have plenty of Torque and are cheap as. Our local rubbish tip/recycling place sell old ones for $5 each...or you can by brand new drills for $30. We then control the motor via a forward and reversible dc speed controller(from ebay)

Works great ,you can go slow it to 1 frame every few seconds up to 30+fps.

Works great, might be to noisy for some people but doesn't bother us. We just close the door to that room while its scanning.

Miles